Was ist CO2-Schneestrahlreinigung?

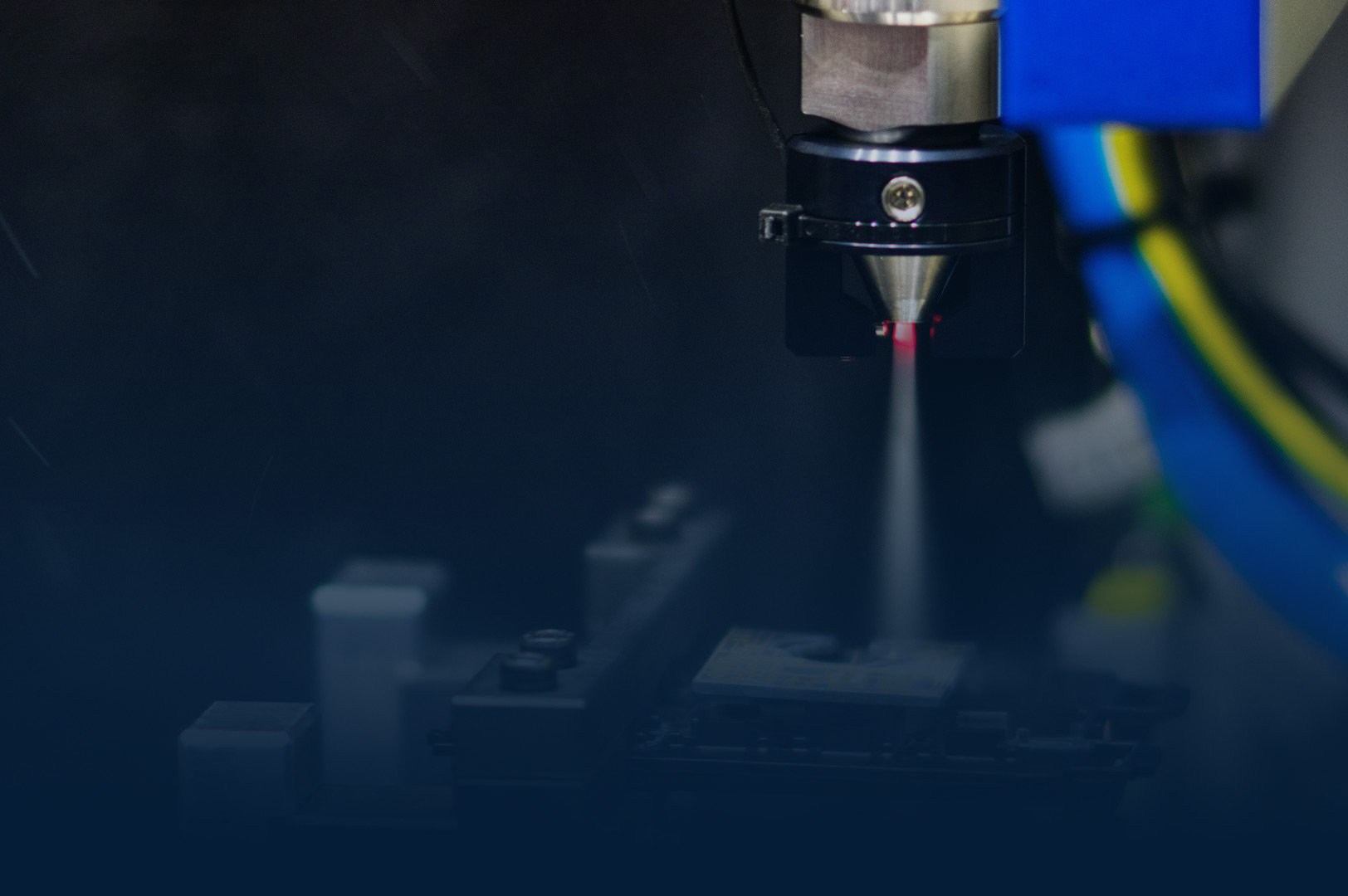

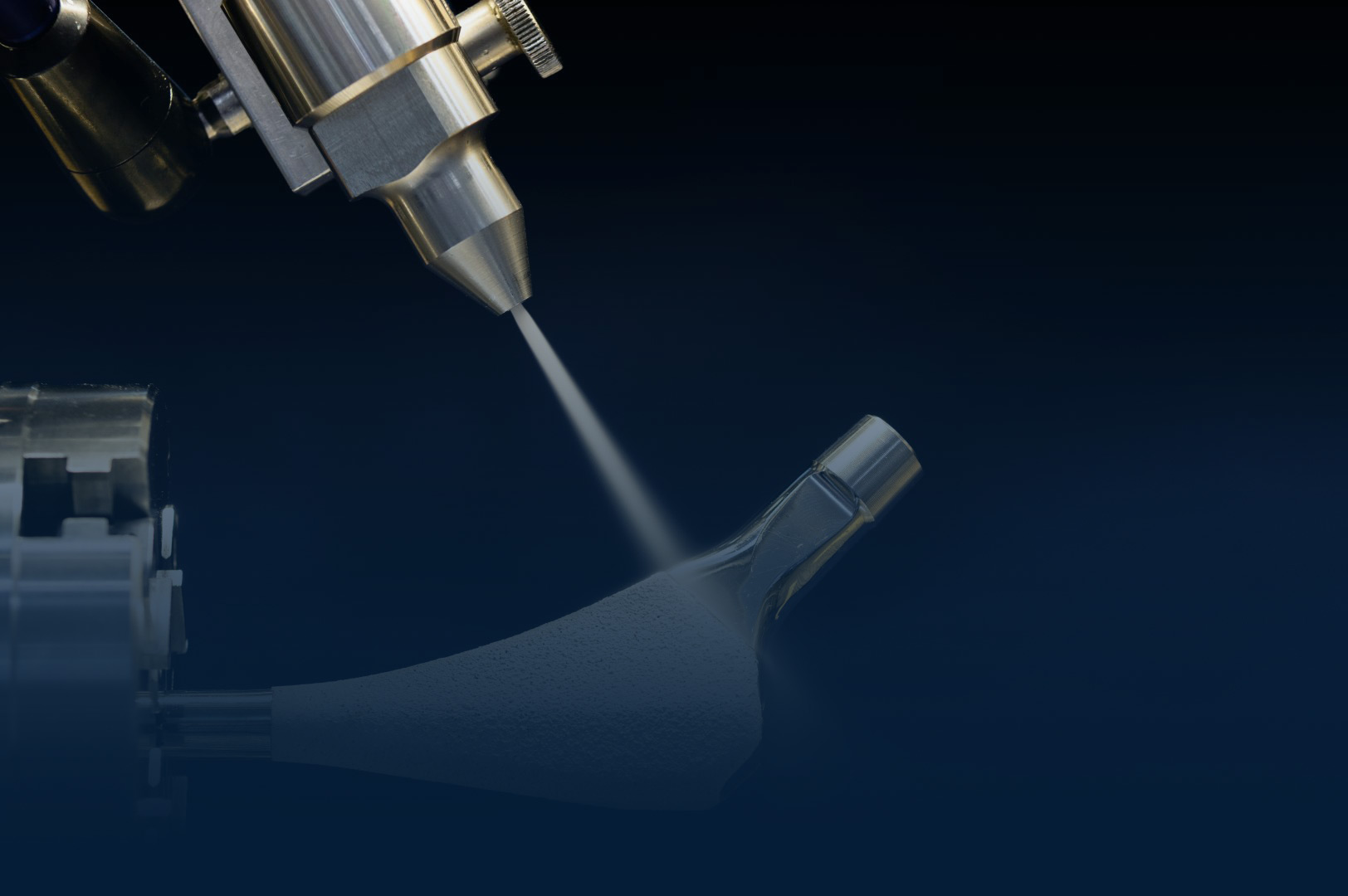

Das CO2-Schneestrahl-Reinigungsverfahren mit der quattroClean®-Technologie ist heute unsere führende Technologie und bietet eine Alternative zu chemisch basierten Nassreinigungsverfahren.

Das Ziel ist es, Produkte in einem trockenen, umweltbewussten und nachhaltigen Prozess von Partikeln und filmischer Kontamination, organisch und anorganisch, zu befreien. Mit diesem schnellen und effizienten Verfahren können wir Rückstände selektiv aber auch von Flächen entfernen – ganz ohne Abwasser oder Chemierückstände.

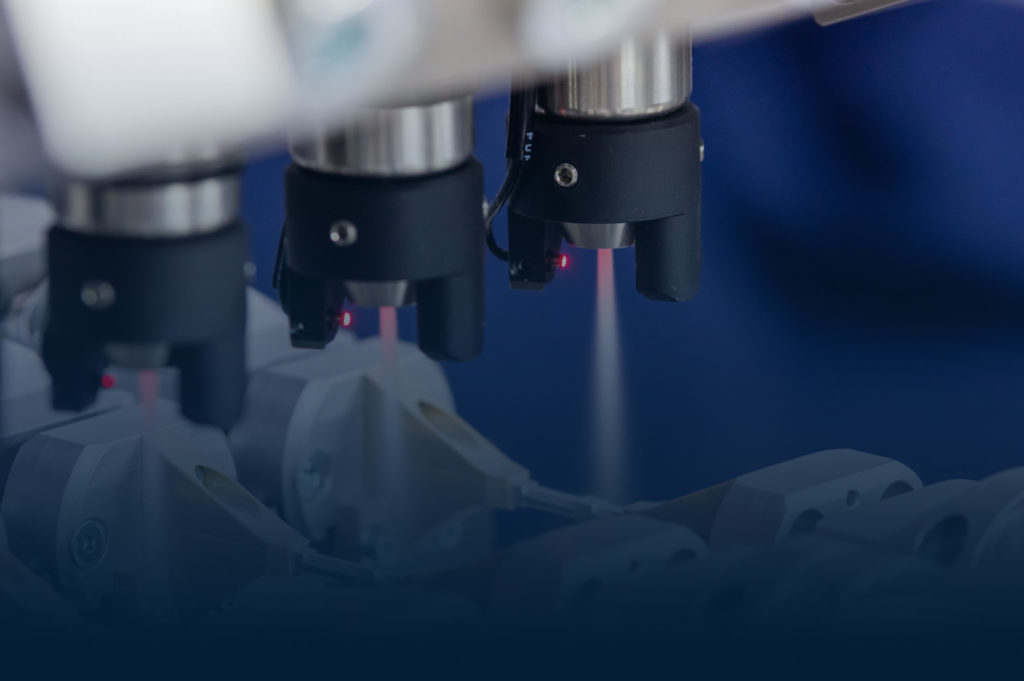

Die Technologie lässt sich als Standalone-System oder als Modul in bestehende oder neue Produktionslinien integrieren – unabhängig vom Automatisierungsgrad der Produktionslinie.

Kontaktieren Sie uns

Kontaktieren Sie uns